New technology of lining construction for induction smelting furnace

1、 Overview

The high temperature performance of induction furnace lining mainly depends on the physical and chemical properties and mineral composition of refractories used. On the premise of selecting raw and auxiliary materials, sintering process is the key process to obtain good microstructure of furnace lining and give full play to its high temperature resistance. The densification of furnace lining is related to the chemical composition, particle size ratio, sintering process and sintering temperature of refractory. Through years of continuous exploration and production test, a reasonable furnace building and knotting process and baking and sintering process were summarized in a factory, which greatly increased the furnace life. The furnace life of dry knotting lining of 2T medium frequency smelting furnace (after one intermediate repair) was as high as 1157 heats, and remarkable economic benefits were obtained.

2、 Furnace building technology

(1) Remove the mica paper when building the furnace.

(2) The crystal quartz sand for furnace construction was treated as follows: 1. Mainly remove lumps and other impurities. ② Magnetic separation. Magnetic impurities must be completely removed. ③ Dry ramming material. It must be dried slowly at 200-300 ℃ for more than 4 hours.

1. Selection of binder

Boric anhydride (B203) was used instead of boric acid (H3BO3) as binder, and the addition amount was 1.1% ~ 1.5%.

2. Selection and proportion of furnace building materials

(1) It should be noted that not all the silica sand with 99% SiO2 & Ge; can be used as lining material of induction furnace, but the size of quartz grain is important. The coarser the grains, the less the lattice defects, the better (such as crystal quartz sand with high purity of SiO2, white and transparent appearance), and the larger the furnace capacity, the higher the requirements for the grains.

(2) The grain size composition and proportion of quartz sand for furnace lining: 3.35-1.70mm (6-8 mesh) 10% - 15%, 1.70-0.85mm (10-20 mesh) 25% - 30%, 0.85-0.425mm (20-40 mesh) 25% - 30%, 0.053mm (270 mesh) 25% - 30%.

3. Knotting of furnace lining

The knotting quality of furnace lining is directly related to the sintering quality. The results show that when the quartz sand particle size distribution is uniform, there will be no segregation, the density of the sand layer after knotting is high, and the probability of cracks after sintering is reduced, which is conducive to improving the service life of the induction furnace lining.

(1) Dry knotting lining (taking 2T medium frequency coreless induction furnace as an example)

The induction coil of induction furnace is coated with insulating mortar layer. Compared with the commonly used insulating materials such as mica and glass cloth, the coil insulating mortar has the following advantages: ① after drying, the coil insulating mortar layer with a thickness of 8-15mm has good insulating performance, which can completely replace mica and glass cloth as the insulating protective layer between the coil and furnace lining; the thermal conductivity of the mortar material is good The coefficient is high, so it is not necessary to worry that the relatively thick mortar layer will affect the three-layer structure of hot surface lining. ② The mortar layer is located between the coil and the insulation layer. Under normal circumstances, the ambient temperature is very low (< 300 ℃), and occasionally when liquid metal approaches its surface, the mortar layer will release a small amount of residual water, which will reduce the insulation resistance, and the system will provide an early alarm. ③ The fire resistance of the mortar itself is higher than 1800 ℃. When the metal liquid seeps to the surface occasionally, the mortar can form a protective barrier for the coil. If there is an alarm, the mortar layer can provide a certain accident handling time. ④ For the ejecting furnace, the cement is made into a taper shape to avoid the friction between the lining and the coil. At the same time, the strength is used to fix the coil, which avoids the deformation of the coil in the process of using, building and dismantling the furnace, and prolongs the service life of the coil. ⑤ Although the coil and cement layer are used as the permanent lining of the furnace, the one-time cost is high and the construction period is long, but its service life can be the same as that of the coil, and it can also be partially repaired, so the overall cost of furnace construction is reduced.

Before dry knotting furnace lining, a layer of asbestos board and a layer of glass fiber cloth should be laid in the insulation layer of furnace coil. In addition to manual leveling and compaction of each layer of materials, spring coils should be used to tighten up and down. When tamping quartz sand, spring coils should be moved from top to bottom one by one until the knotting of furnace lining is completed.

(2) The thickness of knotting furnace bottom is about 280mm, and sand filling is carried out in four times. When knotting manually, uneven density should be avoided, resulting in non compact lining after baking and sintering. Therefore, the feeding thickness must be strictly controlled. Generally, the thickness of each sand filling should be & le; 100mm, the furnace wall should be controlled within 60ram, and many people should operate in different shifts, with 4-6 people in each shift, and each time the knot is tied for 30rain. Rotate slowly around the furnace, and use uniform force, so as to avoid uneven density.

When the knotting of furnace bottom reaches the required height, the crucible mould can be placed by scraping. In this regard, attention should be paid to ensure that the crucible mold and the induction ring are concentric, the vertical adjustment should be made up and down, and the pattern should be closely combined with the furnace bottom as far as possible. After adjusting the peripheral gap, three wooden wedges should be used to clamp tightly, and a heavy object should be lifted in the middle to avoid the displacement of quartz sand when knotting the furnace wall.

(3) The thickness of furnace lining is 110 ~ 120ram, the material is divided into - TTT ~ 1000 type, the material distribution should be uniform, the filler thickness is 60mm, the knot is 15rain (manual knot), until it is flush with the upper edge of induction coil. The crucible mould will not be taken out after knotting, and it will play an induction heating role in drying and sintering.

4. Baking and sintering specifications

In order to obtain the three-layer structure of furnace lining, the baking and sintering process can be divided into three stages

(1) In the baking stage, the crucible mould was heated to 600 ℃ at the speed of 25% h and 50% h respectively, and kept for 4h, so as to completely remove the moisture from the lining.

(2) In the semi sintering stage, the temperature should be raised to 900% at 50 ℃ / h for 3 h, and then to 1200% at 100% / h for 3 h. the heating rate must be controlled to prevent cracks.

(3) In the stage of complete sintering, the sintering structure of crucible is the basis of improving its service life. With different sintering temperature, the thickness of sintering layer is insufficient, and the service life will be significantly reduced.

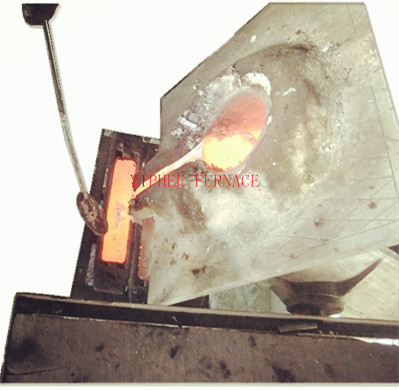

950kg iron was added to the 2T medium frequency furnace to enhance the heating effect of the induction coil. With the continuous baking and sintering, a relatively stable electromagnetic force was generated by low power transmission to stir the molten iron, so that the upper and lower parts of the furnace lining were heated evenly. In addition, the temperature of three phase transformation zones of quartz sand is strictly controlled, so as to promote the full phase transformation of quartz sand and improve the first sintering strength of furnace lining.

3、 Conclusion

For medium frequency and power frequency furnace lining, in addition to ensuring a complete and reasonable three-layer structure, we should also pay attention to the usual operation. When building the furnace, we should choose high-quality and clean furnace building materials, make reasonable proportion, carefully knot, adopt scientific baking and sintering specifications, and strictly operate the process, so as to prolong the service life of the furnace and obtain better economic benefits.